Peroxygen

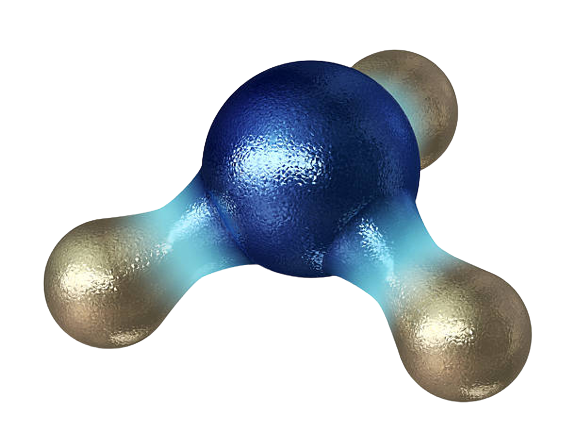

Hydrogen peroxide is a chemical compound with the formula H₂O₂. In its pure form, it is a very pale blue liquid that is slightly more viscous than water. It is used as an oxidizer, bleaching agent, and antiseptic, usually as a dilute solution in water for consumer use, and in higher concentrations for industrial use. Hydrogen Peroxide It is used as a disinfectant, antiseptic, oxidizer, and in rocketry as a propellant. Peroxygens have an invisible, yet substantial presence in our everyday lives ౼ from the food and water we consume, to the products we love, to the personal care items we buy for our families. Solvay, the industry leading peroxygens supplier, delivers on its promise of effective, clean products that meet the highest quality standards across several markets.

Overall, synergism between the antimicrobial activity of biocides can be difficult to demonstrate because the activity may not be specific due to a true synergistic activity between biocides but rather each biocide working independently in the mixture as antimicrobials. Despite that, many reports in the literature suggest synergistic or combined antimicrobial effects with HP. The first, already suggested earlier, was reported in 1930,23 where activity against E coli and S aureus was increased 100-fold when one part of cupric and ferric ions were added to 500 parts of HP. They knew that these ions promoted the free-radical oxidation of organic compounds with HP and concluded that the bactericidal action resulted from the same cause. The supposition that free radicals were responsible for this action was reinforced when it was observed that these metals with HP in a Fenton-type reaction produced mutations in bacteria, like those produced by radiation.

When spores of Clostridium bifermentans were treated with 100 µM of copper sulfate or 0.28 M HP at 25°C, copper alone showed a minimal effect (95% colony formation) and peroxide alone was similar (87%). When used together, the colony formation was significantly reduced (to 0.028%). Because HP is known to remove protein from spore coats, they tested it with dithiothreitol, which also possesses that property. Treatment with HP alone gave 93% colony formation and with dithiothreitol alone, 40%. Together, they gave 0.082%, a 500-fold reduction. It was proposed that dithiothreitol removes the protein in the spore coat that protects the spore from HP and that copper increases the rate of breakdown of HP and the rate of cleavage of peptide bonds by HP.

Studies with plasmid DNA showed that 10-2 M Cu+2 or 10-2 M HP alone did not significantly break the DNA, but a mixture of 10-6 Cu+2 with 10-5 M HP resulted in strand breaks and inactivated transforming ability. The Cu+2 plus HP caused greater damage to the bases in DNA than Fe+3 plus HP.60 Working with five representative viruses, it was found that the cupric and ferric ions alone were virucidal, but this action was greatly increased with HP, particularly for copper.61 This effect extended for all of the viruses, and the investigators indicated that 0.05% Cu+2 plus 5% HP would have the virucidal activity equal to 2% glutaraldehyde. They stated that the Cu+2-HP system was more efficient in their tests than glutaraldehyde and would inactivate most or all viruses that contaminate medical devices.

Peroxygen have an invisible, yet substantial presence in our everyday lives-from the food and water we consume, to the products we love, to the personal care items we buy for our families. Solvay, the industry leading Peroxygens supplier, delivers on its promise of effective, clean products that meet the highest quality standards across several markets. Solvay’s impressive portfolio of Hydrogen Peroxide (H2O2) and Peracetic Acid (PAA) Peroxygen solutions leads the industry in a wide variety of markets and applications:

- Pulp & Paper : biodegradable bleaching agents for high quality paper and tissues.

- Chemical : sustainable oxidation routes towards safer and environmentally friendly materials

- Wastewater Treatment : Oxidise and disinfect wastewater to safely secure scarce resources

- Personal Care : enhanced cleaning and brightening agents for new hygienic formulations in oral care.

- Mining : sustainable solutions to enhance mineral recovery that conserves planetary resources.

- Home Care : proprietary cleaning and disinfecting agents to meet all laundry needs.

- Propylene Oxide (PO) : produce vital intermediates for insulation without by-products Aseptic.

- Packaging : highly effective packaging sterilizing agents for assured food safety.

- Cleaning in Place : powerful yet gentle machinery disinfectants for the safe consumption of processed food.

- Aquaculture : disease treatment and water conditioning solutions for healthy salmon and shrimp.

- Electronics : efficient cleaning to produce high-quality semiconductor wafers.

- Healthcare : Qualified biocides for isolator, restricted access barrier systems (RABS) and room decontamination. Good Manufacturing Practice (GMP) and Active Pharmaceutical Ingredient (API) approved products for wound disinfection and contact lens cleaning.

- Gas Scrubbing : agents to detoxify gases and recover valuable materials for cleaner air.

- Soil Remediation : Technology removes harmful pollutants to safely return land to nature.

- Textiles : gentle bleaching agents for whiter fibers.

| Hydrogen peroxide concentration, % | 35.0-36.0 |

|---|---|

| Residue on Evaporation, ppm, max | 300 |

| Free Acid (as H2SO4), ppm, max | 300 |

| Stability, %, min | – |

| Phosphate, ppm, max | 62.5 |

| Heavy metal (as Pb), ppm, max | 10 |

| Arsenic (As), ppm, max | 4 |

| H2O2 Concentration (w/w) | 35% or 50% |

|---|---|

| Acidity (as H2SO4), ppm, max | 300 |

| Dry Residue, ppm, max | 60 |

| Phosphate (PO4), ppm, max | 50 |

| Heavy Metal (as Pb), ppm, max | 10 |

| Tin (Sn), ppm, max | 10 |

| Iron (Fe), ppm, max | 0.5 |

| Arsenic (As), ppm, max | 3 |